General Manufacturing Leverages Automation Technology for Productivity Gains

General manufacturing companies are involved in the fabrication, processing, and preparation of products from raw materials and commodities into components, assemblies, and final consumer products across a wide variety of industries. This includes manufacturing companies that produce all of the world’s foods, chemicals, textiles, machines, and equipment. Some of the primary categories of general manufacturing include apparel, chemicals and plastics, electronics and electrical equipment, fabricated metals, food and beverage, furniture and fixtures, machinery, paper, printing, rubber, stone, and much, much more.

General manufacturing companies have depended on machinery and the tenets of automation since Henry Ford’s first production lines. In short, automation technology helps manufacturers to increase productivity, while reducing defects and waste. Traditionally, automation technology has helped companies to perform tasks or produce products that wouldn’t be possible with human labor alone, such as stamping metal parts. Automation technology has also improved product quality by providing automated machine vision and other quality assurance and product inspection systems, reducing waste. Today, advanced automation systems continue to fulfill these critical roles of capability and productivity, but it’s also helping to solve traditional labor gaps in key skills, such as welding and quality inspection, especially during uncertain times.

Automation Integration Skills for Every Manufacturer

The breadth of the North American manufacturing sector requires an equally broad automation integration skill set. That’s why Edgewater Automation offers manufacturers every engineering discipline including mechanical, electrical, electronic, and cross-discipline mechatronic design capabilities.

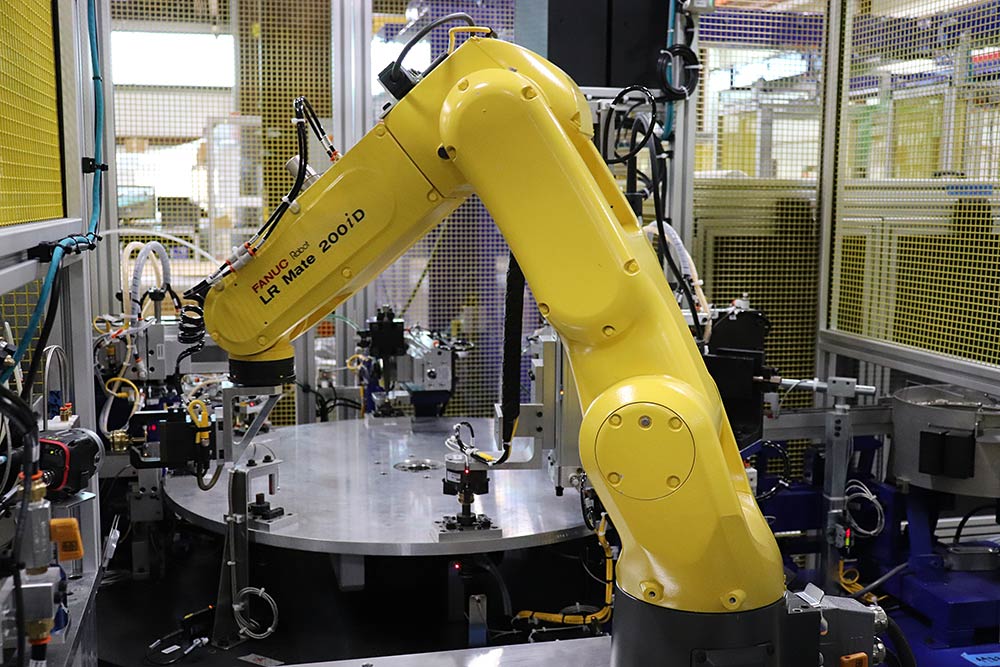

Edgewater is well versed in controls and hardware design, Solidworks 3D and AutoCAD, simulation, software design, programmable logic controllers (PLCs), robotic design and programming, machine vision, motion control and automated material handling, and conveyance, among other general manufacturing solutions.

To make sure manufacturing applications are serviced from end-to-end, Edgewater also offers full product installation, on-site training and documentation, remote troubleshooting, maintenance, and spare parts and service. As an ISO 9001:2015 certified company, Edgewater’s processes are held to the highest quality standards, giving our manufacturing customers the confidence they need in Edgewater’s solutions and services.

Manufacturing Assembly, Material Handling, and Process Development

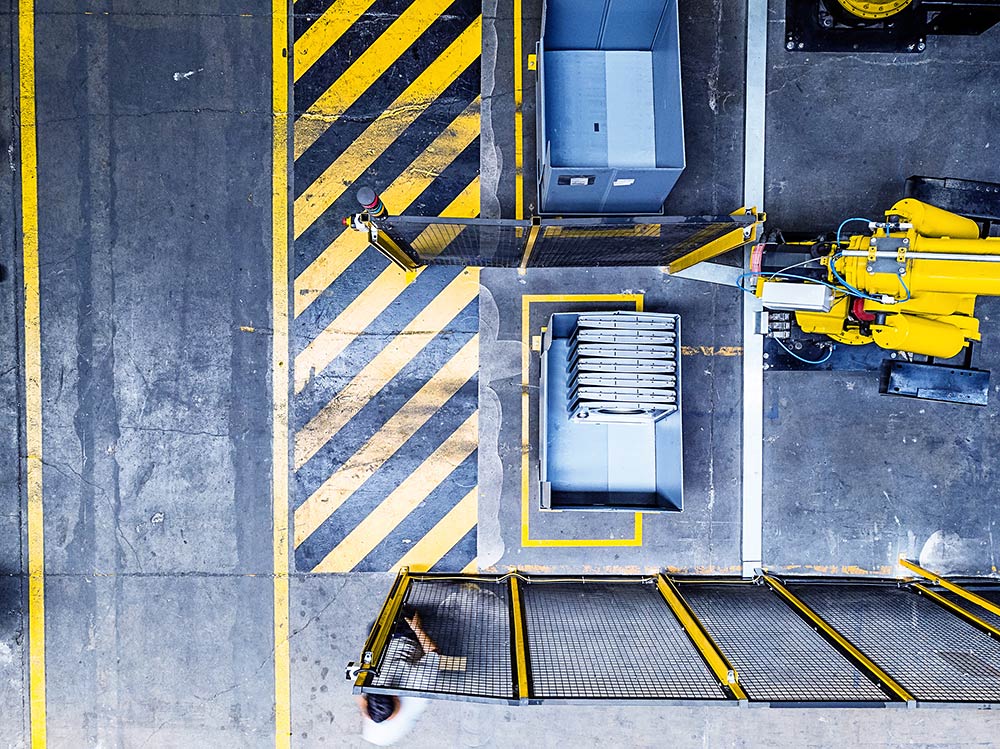

Manufacturing assembly systems, material handling, and process development are common needs from manufacturers. Edgewater begins process development with a careful evaluation of the product and application needs with the customer team. Additional steps include design of experiment (DoE), simultaneous engineering (SE), prototyping, 3D printing, and design for manufacturing (DfM).

As part of defining the general manufacturing process is defined, we carefully evaluate the material handling requirements, including parts feeding bowls and trays; dispense and cure application needs, including fluids, potting, induction/convection curing; and determine packaging solutions, such as stacking/destacking, palletizing/depalletizing, kitting, wrapping, and product tracking.

For assembly systems applications, Edgewater has experience automating numerous assembly systems including product classification systems such as select fit assembly; pressing operations that use servos, hydraulics, or pneumatic actuation; torque applications using either DC drivers or pneumatic power; and of course, welding applications in ultrasonic, laser, resistance, TIG, MIG, and all common metal joining solutions.

Driving Quality Through Data Acquisition and Advanced Test Equipment

During the manufacturing process, data collection in the form of laser and other direct part-marking solutions, labeling, print and apply, angle and distance monitoring, reject containment, and recipe controls are all important to quality production and fast product change over.

Once manufactured, assemblies need to be tested and inspected for quality. Edgewater regularly fields interim production and end-of-line (EOL) tests, including pressure decay, flow, vacuum, mass spectrometry, and torque tests for process control and product evaluation. Our electrical engineers can also help with continuity, High Potential (hi pot), digital resistance, and other important electrical parameters.