Whether you need to assemble a product, verify a widget is exactly what it is supposed to be through automated quality assurance, use material handling to move a product from one place to another, or machine vision to track a process, or explore the engineering feasibility of a new automation manufacturing solution, Edgewater Automation are experts in our core competencies including assembly, industrial test systems, material handling systems, data acquisition and fabrication and machining. Let Edgewater Automation help guide you, design, and integrate the automation technologies today that will help you succeed in tomorrow’s marketplace – whatever the manufacturing challenge you are facing.

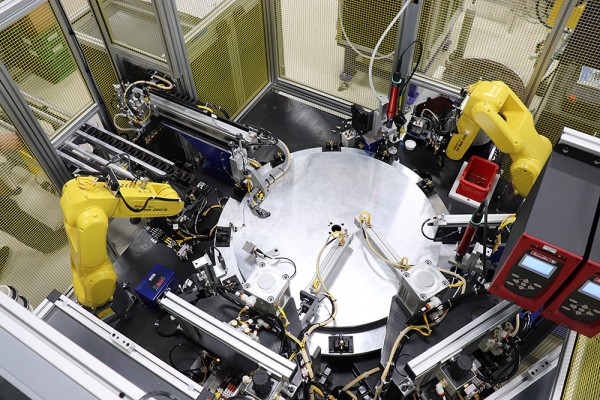

Assembly Systems

Armed with in-depth knowledge of our client’s production goal and the environmental conditions, Edgewater proceeds with an initial automated assembly solution design, leveraging our decades of expertise and extensive ecosystem of automation equipment and component suppliers. We then work with the client to refine the assembly solution design before moving into feasibility testing and system development at one of our production facilities. Finally, once the system is fully constructed and performance is confirmed, we install the equipment. And finally, we make sure our client’s engineers, operators, technicians, and maintenance personnel have the training, documentation, and knowledge they need to keep the system in tip-top operational condition. Have questions about automated assembly solutions, including select fit, torqueing, welding, pressing, assembly verification and more?

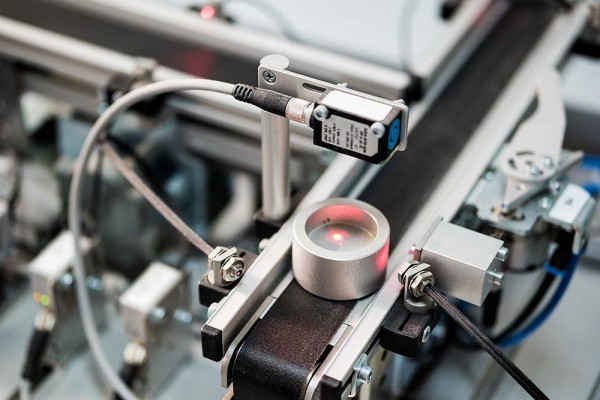

Test Systems

Engineers cannot manage what they cannot measure. Test equipment, including systems for in-process control and automated quality assurance, provides the measurements that managers, engineers, and operators need to optimize a specific process or piece of equipment. With the goal of continuous improvement through statistical process control (SPC) in mind, Edgewater has acquired extensive test system expertise and capability for many industries, including in-process variation test systems, end-of-line (EOL) assembly verification, defect analysis and automated quality assurance systems, such as off-line coordinate measurement machines (CMM), and in-line machine vision systems. Additional industry test processes include pressure decay leak tests, flow analysis, vacuum testing, and mass spectrometry, to name few.

Material Handling Systems

Material handling refers to everything that happens after a product is manufactured: the movement, storage, and control of products and materials from the manufacturing plant, through warehousing and distribution, to the end user. Edgewater regularly helps design and develop material handling systems that include a combination of manual, automated, and autonomous solutions. Dock workers, for instance, manually unload a truck, while an automated fixed-camera machine vision system scans the pallet bar code as it passes through the shipping doors, and an autonomous forklift carries the pallet from the staging area to final rack and storage. To find out more about parts feeding, packaging, dispense and cure and the many material handling solutions Edgewater has developed for its industrial customer base.

Data Acquisition & Management

The Industrial Internet of Things (IIoT) and machine-to-machine communication common to Industry 4.0 widely leverage internal sensors and data collection systems to monitor machine operation data and share that data with upstream/downstream systems and networks. While technicians and maintenance personnel used to be the only plant employees interested in data acquisition systems (DASs)(DAQ), today’s discreet and process manufacturers alike leverage machine performance data across the enterprise — in the front and back office. Operational equipment yields information about the efficiency of manufacturing equipment, sources of rework and material loss, and opportunities to improve productivity. It is not an overstatement to say that data acquisition systems are the new heart and blood of the modern enterprise. With this in mind, it’s critical for Edgewater Automation customers to fully understand the sources, methods, management, and utilization of data acquisition systems and their ability to provide insights that can lead to process and production improvements. For more information on DAS/DAQ solutions, including laser marketing, labeling, print and apply, force and torque monitoring, angle and distance monitoring, reject containment, recipe control and more base.

Edgewater Fabrication, Manufacturing & Machine Shop

Need burst capacity? Need small to large part runs? Need a field engineering service visit to help design that new mezzanine? Edgewater has you covered. Edgewater Automation started a fabrication, manufacturing, and machine shop team because of our own need for quicker turnaround of fabricated and machined metal and plastic parts for the automated systems we build. The ability to fabricate, manufacture, and mill our own metal and plastic components on-site gives Edgewater the flexibility to respond to changing application needs without incurring undo delays. Having our own fabrication, manufacturing, and machine shop also allows us to control part quality, reliability, and cost. Whether you need contract manufacturing of regular production parts, small to large production runs, machining, engineering, assembly, or painting, Edgewater Fabrication, Manufacturing & Machine Shop has the capabilities and capacity you need to succeed.