Data Acquisition Systems (DAQ or DASs) and Management

The Industrial Internet of Things (IIoT) and machine-to-machine communication common to Industry 4.0 widely leverage internal sensors and data collection systems to monitor machine operation data and share that data with upstream/downstream systems and networks. While technicians and maintenance personnel used to be the only plant employees interested in data acquisition systems (DASs)(DAQ), today’s discreet and process manufacturers alike leverage machine performance data across the enterprise — in the front and back office. Operational equipment yields information about the efficiency of manufacturing equipment, sources of rework and material loss, and opportunities to improve productivity. It is not an overstatement to say that data acquisition systems are the new heart and blood of the modern enterprise. With this in mind, it’s critical for Edgewater Automation customers to fully understand the sources, methods, management, and utilization of data acquisition systems and their ability to provide insights that can lead to process and production improvements.

Data Acquisition System Sources and Interfaces

Today’s manufacturing plants have many different data networks powering layers of enterprise software and data collection. Some of the most common sources of data for DAQ/DAS include supervisory control and data acquisition (SCADA) software systems used to control manufacturing equipment and processes. For larger networks with more than 3,000 data collection points, distributed control systems (DCSs) are a common architecture, while individual machines are often directed by programmable logic controllers. All of these systems generate data that provides insights into the efficiency of plant operations, sources of potential defects and loses, and liability protection in the form of auditable production records. In addition to general architectures, Edgewater helps our customers to choose the best interfaces for their data acquisition system, whether it be object linking and embedding (OLE) for open process control (OPC) or variants such as OPC-DA for data access, OPC for historical data access (OPC-HDA), or universal file and stream loading (UFL) using ASCII sources.

Best Data Acquisition System Practices

After reviewing your data collection sources, interfaces, and network needs, Edgewater engineers will help you to develop best practices tailor made for your organization. For example, fast-moving processes produce terabytes or more of data. For many systems, installing buffering to preserve critical data — even in the event of e-stop or other unexpected surge or downtime — is critical. Backup and archiving schedules also help make data acquisition systems more reliable and robust while ensuring your organization has the historical data it needs to make smart decisions about future operations. Edgewater engineers will help you sort equipment into classes based on reporting frequencies so you don’t miss critical inflection points, and we can help develop metadata that helps preserve the automation expertise long after Edgewater engineers have installed and trained your personnel in best data acquisition practices.

Leveraging Data Acquisition Systems for Continuous Improvement

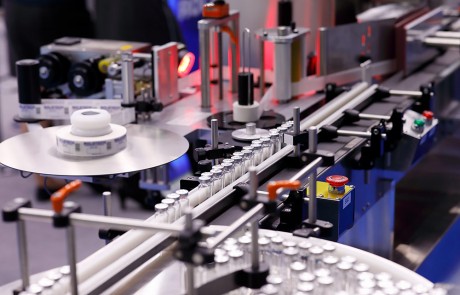

Data acquisition systems aren’t about collecting data for data’s sake. Edgewater Automation can help you use data to improve operations, develop new business, and expand capacity. For example, Edgewater specializes in laser marking, labeling, and print-and-apply systems for product tracking. Moving from batch testing and inventory tracking to 100% production tracking allows companies to clearly identify steps in the process that lead to loss and rework while tracking products from production through distribution to the end user, limiting returns and shipping errors. These efficiency improvements mean operations personnel can focus their attention on higher-level matters, expanding capacity and improving customer relations. At Edgewater, data acquisition systems are the heart that propels our customers to new levels of business success.